Inventory and production go hand-in-hand; it’s your biggest asset. Inventory affects how much product you can produce, impacting your company’s profitability. Production metrics generally include efficiency, yield, and productivity, but know that these can work against your efforts to reduce inventory costs. Increasing raw material yields to stored finished goods is not advantageous. Having finished goods on hand can be risky if the customer wants to make a part revision or damage could occur.

Poor inventory accuracy can indirectly bog down your business in many ways. Carrying too much makes the out-of-pocket investment associated with that inventory too high. Other costs of holding too much inventory are less obvious, though. For example, the inventory cost and the indirect labor that goes into managing it, including material handling, computer data entry, and scanning, all cost you something. You also have to consider the storage space, property taxes, electricity, heating, and cooling costs. Valuable resources are being misused. The same can be said for finished goods.

Those are only internal impacts of inventory accuracy. When faced with challenges managing the supply chain and inventory, businesses often struggle to plan and schedule customer orders on time. Too little inventory can lead to poor customer experiences with long-lasting, irreversible effects. Ultimately, it can immobilize an operation if these two areas can’t work seamlessly together.

Inventory Accuracy Explored

Inventory accuracy is any inconsistency between your recorded and actual inventory, including its quantity, location, and value. Sources claim that 97% accuracy is a good benchmark for most companies. Remember that each dollar of inventory error is a dollar of lost profit. Evaluate your turns. If your turns are low and you are holding more inventory than you need, either because you bought or made too much, educate your employees on best practices.

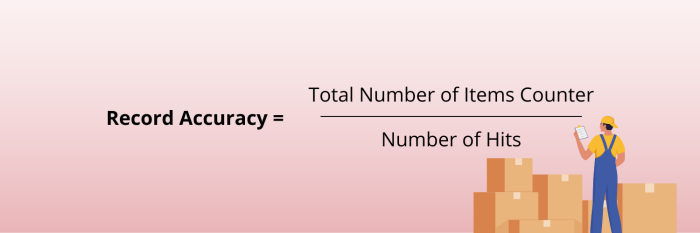

The first step to calculating inventory accuracy is to count the number of items. If the count equals the on-hand value in the system, it is a hit. If it does not equal the on-hand value, it is a miss. Then use the formula pictured below to see your inventory accuracy.

This pure number does not account for inventory value or categorization techniques like the ABC analysis (with A items having a very tight inventory control, B items less tightly controlled, and C items with the simplest inventory control). Read more to learn how to calculate inventory from a value perspective and explore the inspiration for this article.

Benefits of Accuracy

Now that we’ve discussed the relationship between inventory and production, why it’s important, and how to calculate inventory accuracy, let’s talk about the benefits you’ll see.

Make sure everyone in your company, from the front office to the floor, understands the importance and impact of inventory control to make better-informed decisions.

How Infor CloudSuite Industrial Powered By Syteline Can Be an Asset

Infor CloudSuite Industrial powered by Syteline is an ERP solution that has simplified complex manufacturing for the SMB market for over 30 years. An easy-to-use, robust ERP system gives you more control over your inventory by providing greater discipline, accuracy, and immediate access to supply information throughout the company. It helps maintain raw materials, WIP, and finished goods inventory quantities while allowing you to easily track material and costs on a per-project basis.

In addition, it optimizes the supply chain to improve visibility and control costs with sourcing, procurement, and shipping and receiving. Plan in advance by eliminating siloed data, connecting it all in one system to generate accurate promise dates, plan materials, and maintain your capacity. Strong inventory management and production planning will help elevate your business to the next level.

Is Your Plant Making One of These Three Biggest Mistakes?